“I Helped SpaceX Secure Their First Commercial Contracts": Serial Space Entrepreneur Robert Feierbach on Building Billion-Dollar Ventures Across Four Continents

Space entrepreneur Robert Feierbach shares how he secured SpaceX's first contracts, pioneered satellite technologies, and is now building North America's newest spaceport after a 30-year career spanning four continents.

In the rarified air of La Paz, Bolivia, a seven-year-old boy discovered meteorite fragments scattered across the Andean hillsides – teardrop-shaped stones that would spark a lifelong fascination with space. Decades later, that same boy would become one of the most influential behind-the-scenes architects of the commercial space industry. Robert Feierbach doesn't just speak seven languages – he speaks the universal language of making impossible deals happen. From convincing skeptical satellite operators to trust an unknown startup called SpaceX, to pioneering Europe's first major satellite broadband service, to now building North America's newest spaceport, Feierbach has been the invisible hand behind some of the most pivotal moments in commercial space history.

But unlike the rockets and satellites he helps put into orbit, Feierbach's most powerful tool isn't technological – it's his ability to bring the right people together at the right moment. "The space business isn't really about rockets and satellites," he reveals, "it's about bringing the right people together to make impossible things happen." This is the story of how a boy who once couldn't see the stars clearly became the man who would help others reach them.

Your career spans over 30 years in space and aerospace technology. What first sparked your interest in space, and how did that lead to your early work in the industry?

"Many of us have different ways we entered the space industry, or something that ignited our passion for it. In my case, there were a few defining moments.

When I was about two years old, my father moved our family from California to Bolivia, where we lived in La Paz, high in the Andes. Around age seven, while walking on a hillside, I noticed these small, tear-shaped molten rocks, all pointing in the same direction. I asked my dad about them, and he explained that they were likely created when a meteorite struck the ground, melting upon impact and forming teardrop-shaped stones. The idea that something could come from space and land on Earth fascinated me.

The real breakthrough, though, came when I was around eight or nine years old and finally got eyeglasses. I hadn’t realized my vision was poor, and when I put on my glasses for the first time, I could suddenly see the stars in vivid detail. In Bolivia, the skies were incredibly dark, and I was amazed to discover billions of stars for the first time—something I had been missing all along.

During college, I developed a deep interest in telescopes and space. While studying at the University of Utah, I had access to the astronomical observatory. If I rented it on a Friday afternoon, I had it for the entire weekend. I’d spend my nights observing planets and constellations, completely immersed in space exploration.

My entry into the space industry, however, happened professionally. After earning my MBA at Thunderbird in Arizona, I was recruited by a small company at the time—EchoStar, which later launched the Dish Network. They needed international MBAs who spoke multiple languages to expand into Europe. I took the job, moved to the Netherlands, and spent three and a half years there. I worked extensively across Africa, the Middle East, and Europe, bringing satellite television to regions where people had never had access to it before. It was incredibly rewarding.

That experience set the foundation for my career, and I’ve never left the space industry since. Over the years, I’ve worked in analog and digital TV, broadband satellite services, in-space manufacturing and operations, and rockets. I don’t think I’ll ever leave the industry until I retire."

As President of Maritime Launch USA Inc. and having worked at SpaceX during its early commercial development, how do you see the commercial spaceport landscape evolving over the next decade? What unique advantages does Spaceport Nova Scotia offer compared to existing launch facilities?

"At SpaceX, I got firsthand experience working for a startup that, at the time, had no track record. They brought me on because of my industry contacts with satellite operators. They needed people who already had relationships in the industry to help sell their launch services. At first, we were seen as 'crazy cowboys from California' with no credibility.

Over time, though, SpaceX proved that lower-cost launches were possible. Take reusable boosters, for example—just recently, one was flown for the 28th time. Originally, boosters weren’t designed for repeated use, but now they are. Ideally, a spacecraft could be used 100 times, only requiring refueling, which will further reduce costs.

By 2016, we recognized that major U.S. spaceports were getting overwhelmed with traffic. Today, it’s even more extreme, with rocket launches happening every two or three days, compared to just 20-30 per year in the past. A letter from the US Space Force even highlighted the risk of over-reliance on two spaceports—Kennedy Space Center (KSC) and Vandenberg. Losing one would cripple U.S. launch capabilities, which is an unacceptable risk.

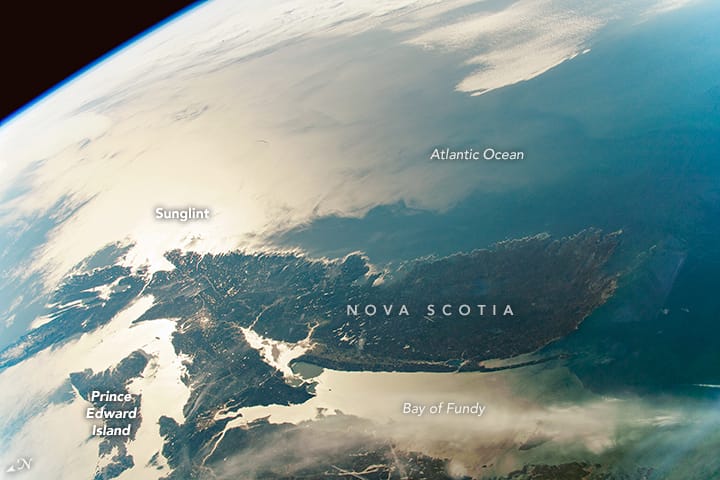

When evaluating new launch sites, we identified Nova Scotia, Canada as a prime location. It sits at the farthest northeastern point of North America, allowing for eastward and southward launches over open ocean—ideal for both inclined, polar and SSO orbits. Essentially, it combines the advantages of both KSC and Vandenberg in one site.

Nova Scotia also has excellent logistics infrastructure—air, rail, roads, ports, and deep-sea access for rocket transport. Halifax, with a population of 500,000 and multiple universities, provides a strong talent pool. Unlike other remote launch locations, it offers a high quality of life and accessibility.

Another advantage is minimal air traffic disruption. Across Nova Scotia, flights from North America to Europe occur from 5-7 PM, and return flights happen between noon and 3 PM. Since they mostly fly inland, not over the ocean, our site offers very flexible launch window opportunities for frequent and safe launches.

In 2022, we received environmental approval for a medium-class rocket capable of delivering five tons of payload to low Earth orbit (LEO). In 2023, we launched a suborbital test rocket to validate procedures. In 2024, the U.S. and Canada agreed on the terms of a technology safeguard agreement (TSA), allowing U.S. technology to be launched from Canada.

Now, we're developing the first of three dedicated launch pads for different operators, with a second phase planned for larger medium-class rockets. Given the congestion at existing spaceports, the timing is perfect for our offering to the market."

At SSL (now Maxar), you led development of the world's first fully-featured robotic GEO servicing system. What specific technical and business challenges did you face in bringing this innovative technology to market?

"The project, developed under DARPA’s RSGS (Robotic Servicing of Geostationary Satellites) contract, aimed to build a GEO servicing spacecraft with two fully articulated robotic arms. These arms were equipped with interchangeable tools—what we called 'end effectors'—capable of inspecting, cutting into, unbolting, upgrading and refueling satellites.

This system enabled servicing of satellites that weren’t originally designed for maintenance. We demonstrated the ability to remove thermal insulation, cut safety pins, unbolt components, and transfer fuel to satellites in space. The idea was to extend the operational life of GEO satellites by offering in-orbit repairs and upgrades.

At the time, around 2,500 GEO satellites were in orbit, representing our addressable market. However, by 2019, the focus of the industry was shifting towards low Earth orbit (LEO) using small spacecraft. Satellite operators hesitated to place new GEO orders. Previously, manufacturers built around 25 new large GEO satellites per year, but by 2019, that number dropped to just five. The market essentially imploded due to uncertainty about LEO’s growing role.

A GEO satellite requires three to four years of financing, design, and manufacturing, then remains in orbit for 15 years.

Imagine creating a high-tech product today and not updating it for two decades—it’s unimaginable! But that's the reality GEO satellite operators face today.

The RSGS project has since transitioned to Northrop Grumman, which is preparing to launch the system soon. However, I expect the focus to shift from satellite servicing alone to broader in-orbit operations—modifying structures, adapting rocket stages for reuse, or even space-based manufacturing. The demand for traditional GEO servicing is shrinking, but on-orbit operations have immense potential."

G-Space is developing AI-powered software for space manufacturing. What specific manufacturing processes do you see being transformed first by this technology, and what technical hurdles need to be overcome?

"G-Space is a young software company based in Silicon Valley, and I’ve been on its board for several years. The company specializes in developing AI-powered tools to analyze data and optimize experiments before, during, and after their time in space. One of their key technologies is ATOM(e) —an experimental AI tool designed to streamline and analyze in-space manufacturing processes.

This technology is critical because running manufacturing tests in space is incredibly expensive and time-consuming. For example, every experiment sent to the International Space Station (ISS) involves extensive paperwork, logistics, and high costs. ATOM(e) allows researchers to model and refine their experiments through advanced simulations before launching them, significantly reducing the number of required spaceflights.

The biggest challenge, however, is that the technology is highly complex. Many potential customers struggle to grasp its benefits immediately. G-Space's CEO, Ioana Cozmuta, is incredibly technical—she thinks on a PhD level, often beyond what many in the industry can quickly process. The key challenge is making the value proposition more accessible and easy to understand. But once customers see the time and cost savings, the impact is clear.

As space manufacturing advances, AI-driven optimization will become even more crucial, allowing companies to develop more sophisticated products while minimizing expensive trial-and-error cycles in orbit."

0-G Launch is developing specialized aircraft for microgravity testing. What specific market demands are driving this business, and how do you evaluate potential customer applications?

"Currently, only two space stations exist—the ISS and China’s Tiangong. However, by 2030, the industry expects at least seven commercial space stations to be operational, including Axiom, Orbital Reef (Blue Origin & Sierra Space), Starlab (Voyager, Nanoracks & Airbus), VAST and others.

This expansion is creating a massive demand for affordable and accessible astronaut training. You can’t just send someone into space without preparation. They need microgravity training to experience and adapt to weightlessness before launching.

To put things in perspective, about 700 people have been to space so far. With commercial spaceflight growing, that number is expected to reach 2,000 by the 2030s and 5,000 by the 2040s. Industry estimates suggest the microgravity training and testing market alone will be worth around $8 billion in the next decade.

At the same time, public interest in space is growing, thanks to companies like SpaceX and Blue Origin. Many people now see space as 'cool' and want to experience microgravity for themselves. This has fueled demand for parabolic flights—flights that simulate weightlessness through a series of sharp 10,000 foot aircraft ascents and descents.

Our company model is to modify commercial aircraft with cutting-edge avionics to offer highly precise parabolic flights. These flights serve multiple purposes:

- Astronaut training before they travel to space.

- Equipment testing to validate hardware in microgravity before launch.

- Public microgravity flights, allowing people to feel what it’s like to float in space.

Unlike traditional microgravity flights, our approach increases efficiency and lowers costs. By using larger aircraft, we can accommodate more experiments, more scientists, and more participants per flight—bringing the cost down for everyone.

We’ve been securing market agreements and letters of intent worldwide, and the demand has been incredible. Governments, research institutions, and private companies all want access to this capability, and we’re well-positioned to bring it to them."

You've secured major contracts in both European and North American markets. Could you walk us through how you approached and won a key satellite contract for the OneWeb constellation?

"MDA Corporation, which was part of the MAXAR/SSL group at the time, wanted to be considered as a vendor for OneWeb’s 650-satellite constellation project, which was owned and managed by Airbus France and OneWeb UK. Because of my long standing relationships with executives at both Airbus and OneWeb —developed over nearly two decades of my work in Europe—I was chosen to lead the discussions and negotiations on behalf of our company.

During OneWeb’s vendor selection process, we identified a key opportunity: their new LEO satellites were incredibly compact—only about one square meter in size. This space constraint required a novel antenna solution that would fit within tight design limits while maintaining high performance.

Our team developed a breakthrough solution—a specialized satellite antenna we called the 'Venetian Blinds.' These ultra-thin, Ku-band antennas were inspired by ground-based radar technology MDA had previously worked on. Unlike traditional satellite antennas with SSPAs and long feeder horns, our 'Venetian Blinds' had an extremely slim profile, making them a perfect fit for OneWeb’s small satellites.

Additionally, MDA had extensive experience manufacturing small parabolic antennas for GEO satellites. We leveraged this expertise to provide OneWeb with dual parabolic steerable antennas for their space-to-ground gateway connections.

In the end, our unique design and industry expertise secured a contract worth nearly $100 million. This deal supplied OneWeb with both the 650 sets of user antennas and the gateway antennas—playing a critical role in the world’s first large-scale commercial satellite constellation.

It was a huge win in a new market segment for the SSL/Maxar/MDA group, and a testament to the power of innovative thinking and strong industry relationships."

About Robert Feierbach

Robert Feierbach is President of Maritime Launch USA, Inc., the US division of Canada’s first and only commercial spaceport based in Nova Scotia, and Founder and CEO of 0-G Launch, a Washington-DC based company deploying a fleet of specially-modified commercial aircraft to provide high-precision microgravity flights and horizontal air-launch services to the fast-growing aerospace industry.

Mr. Feierbach, a well-recognized space industry expert, has an impressive track record in groundbreaking satellite technologies and services around the world, with leadership responsibility in companies generating $150 million - $2 billion in annual revenues. During the past 30 years, he held CEO/CCO/VP leadership positions at Echostar in the Netherlands, SES Global in Luxembourg, various Eutelsat / ViaSat partnerships in France, Italy and the USA, Hughes Network Systems’ International Division, Space Systems Loral (Maxar), and SpaceX, the private rocket company. Mr. Feierbach also led the commercial launch of the world's first Ka-Band spot-beam high-throughput satellite (HTS) for Eutelsat.

Mr. Feierbach holds a Bachelor’s degree in Computer Science Applications from the University of Utah, and an MBA from the Thunderbird School of Global Management. Robert speaks seven languages fluently and has lived and travelled across the Planet.